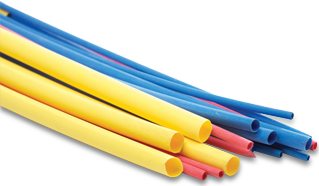

State-of-the-Art Technology in PVC Compounding

Our combination of large and small compounding lines allows Polyflex to handle your large PVC compound production runs as well as smaller specialty orders.

Polyflex currently has five compounding lines with a capacity of 100 million lbs/year at our 55,000+ square-foot facility in Baltic, Ohio.

Dedicated Clear FDA Production Line

The newest addition to our compounding line, our clear production line, is dedicated exclusively to the production of clears. This dedicated line allows us to produce the best PVC compound on the market.

General PVC Line

Profile Line

These lines provide excellent mixing and dispersion capabilities at low temperatures. Precisely controlled shear rates enhance stability and yield a lower memory temperature to the finished compound, resulting in ease of processing for the customer.

Reprocess and Reclaim Line

This line is used for reclaim and reprocessing applications

Our automated bulk solids transfer system, computer controlled and monitored mixing, and automated ingredient addition system assure that compounds are consistently manufactured to specification each and every time.